New insulation material

New insulation material for electric automotive

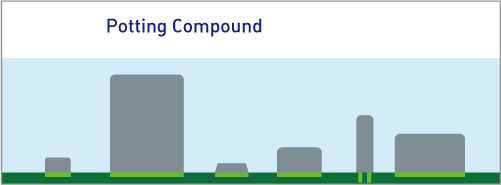

Traditional method to protect the PCB from the invasion of chemicals, thermal shock and other environmental damage are mainly conformal coating and potting material. But the protection ability of conformal coating is not fully satisfied due to the strict requirement of electric automotive industry. And potting material will increase the weight of the cars which is the most critical factor in automotive industry. To meet the light weight requirement, Contin developed a new kind of insulation material which can form a 2-4mm protection layer of on the surface of components which lessen the weight of 70% compared with using potting material. The product meets UL and IPC standard; It is RoHS compliance and REACH approvable. Contin’s technical specialists are available to assist you with new designs, provide production support, and improve performance and line speed in existing applications.

CC21-new general insulation material Outstanding features

• Less weight compared with potting material and low Cost

• Fast pot life to meet production efficiency

• Low Processing Hazards

• Non-MBOCA/Non-TDI

• Fungus Resistance

• Low Exothermic

• Low Shrinkage

• Improved Thermal Shock

• Low Stress on Embedded Components

• Excellent Dielectric Properties

• UL Recognized Systems,

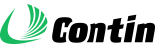

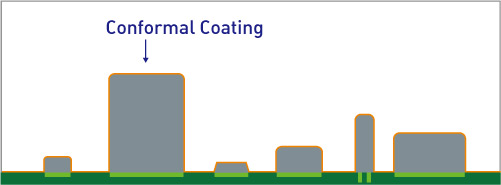

Comparison chart

Coating material cannot provide enough protection for the PCB board.

The thickness of potting material increases the weight of the whole parts.

This new material can form a thin layer on the different side of the PCB component which can provide full protection. At the same time, the thin layer decreases the weight which can meet the requirements of automotive industry.